SOLAR WATER HEATING SYSTEM

Technical Specification

System capacity |

Hot Water Tank Wight |

System Surrounding |

Max. System Outlet Temperature in winter |

3-layer Borosilicate Tube Size (In mm.) |

Hot water storage tank Type

|

Users |

||

100 LPD |

26kg |

1950X900 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

3-4 |

||

150 LPD |

37kg |

1950X1280 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

5-6 |

||

200 LPD |

48kg |

1950X1700 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

7-8 |

||

250 LPD |

59kg |

1950X2100 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

9-10 |

||

300 LPD |

70kg |

1950X2500 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

11-12 |

||

500 LPD |

85kg |

2370X2580 |

60 degree Celsius ± 5 degree |

58X2100 |

Branded GI |

13-15 |

||

500 LPD |

91kg |

3750X1650 |

60 degree Celsius ± 5 degree |

58X1800 |

Branded GI |

13-15 |

||

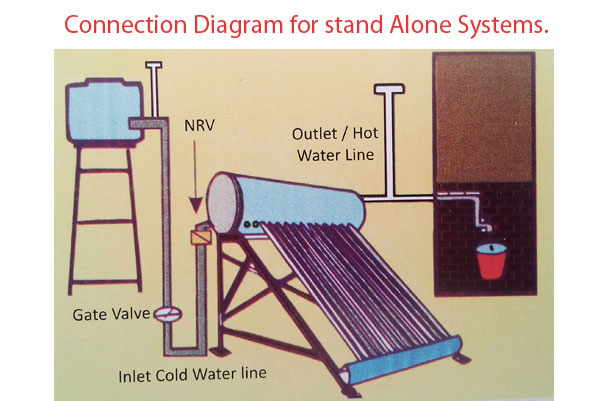

INSTALLATION

1. Handle carefully while transporting, unloading and lifting the system to the terrace.

2. Install the system where it gets maximum sunlight.

3. Assemble the mounting frame of the tank and/ or manifold such that the ETC tubes are facing towards South.

4. Put the Hot water/ Manifold over the frame. Check whether the tank/ manifold holes are facing the holes of the Bottom Support Bracket.

5. Put the Bottom Caps into the Bottom Support Holes.

6. Put anti-dirt seal over the ETC Tubes.

7. Apply some oil or soap water to the Silicon Rubber Grommets and to the end of the ETC Tubes as lubricant.

8. Fix one ETC tube to each end of the Tank/ manifold by slowly screwing it into the tank.

9. Push the ETC Tube down till it gets securely placed in the Bottom Cap.

10. If the alignment is ok. Tighten the bolts under the tank to the frame.

11. Now install all the remaining ETC Tubes.

12. Connect the inlet-outlet pipes to the tank. Fix a non Return Valve (preferably horizontal) and a ball valve to the inlet pipe of the tank as shown in the figure. If it is a manifold system , connect the manifolds to the tank and connect inlet outlet pipes to the tank.

13. Fill up the tank with cold water when the ETC Tubes are cold. Specially early morning before sun rise or after 10 O’clock at night. Check for any leakages. Sometimes, the Silicone Rubber Garmmets are displaced while inserting the ETC Tubes. If there is any leakage form the Anti-dirt seal, remove the tube, place the silicone rubber ring on its seat and reinsert the tube.

CAUTION

The empty system should never be filled with cold water in the afternoon or when the Tubes are hot. Either fill it up before 7 am in the morning or After 10 O’clock at night. Otherwise, the ETC Tubes are prone to crack due to temperatuere shock.

TROUBLESHOOTING

Indications |

Possible Reason |

Remedies |

1. No water in the hot water tap.

|

a. Empty cold water tank |

Fill up the tank

|

2. Low hot water temperature |

a. Poor Sunlight |

Wait till Sun gets brighter |

3. Not water coming out through cold water pipe/ taps |

a. Defective NRV |

Repair/ replace NRV Disconnect |

4. Water leaking through tank. |

a. Silicon rubber grommet |

Place properly or replace silicon rubber grommet. |

IMPORTANT

1. Never fill up the empty system when the tubes are hot. The best time to fill up the tank is before sunrise or after 3 hours of sunset.

2. If there is a wide time gap between 2 subsequent baths, the hot water stranded in the pipeline loses heat . keep the interval between two baths to the minimum.

3. The ETC tube can be descaled by a simple bottle cleaning brush. Periodical cleaning will maintain the operational efficiency of the system.

4. If the ETC tube changes its appearance and look hazy while, it indicates the ETC tube is broken or the vacuum is lost. This will render the tube useless. Get the tube replaced by any authorized person as early as possible.